PosiTector® SmartLink PosiTector RTR Replica Tape Reader probes measure burnished Testex Press-O-Film replica tape to produce peak-to-valley surface profile height measurements. This instruction manual specifically covers use with PosiTector SmartLink. The PosiTector SmartLink and free mobile app allow you to wirelessly connect a wide selection of PosiTector probes to your smart device. Take full advantage of your device's keyboard, microphone, camera, internet data connection, etc. to simplify and enhance your measurement inspection process.

The PosiTector SmartLink measurement solution consists of a PosiTector App, PosiTector SmartLink device and compatible PosiTector probe. In addition to the PosiTector RTR-H, compatible probes include the PosiTector SPG (surface profile), 6000 (coating thickness) and DPM (environmental conditions). Why is Measurement Important? Low profile may reduce coating bond strength (adhesion). Too high and the peaks may receive insufficient coverage and possibly rust prematurely. The costly application of more coating may be required if the profile is too high. For these reasons, surface profile should be measured prior to coating application to ensure that it meets contract specifications. Press-O-Film Replica Tape Placing the compressed tape (replica) into the PosiTector RTR-H probe gives a measure of the average maximum peak-to-valley height of the surface roughness profile. The polyester substrate is automatically subracted from all measurements.  The PosiTector SmartLink powers-up when the LED button is pressed. To preserve battery life, the PosiTector SmartLink powers-down after 5 minutes of no activity. Alternatively, press and hold the LED button until it turns red and shuts off (approximately 5 seconds). All probe settings and calibration adjustments are retained within the PosiTector SmartLink, stored measurement data is retained within the smart device (cell phone, tablet). Measure To ensure best accuracy, the probe should be zeroed before each use. It is therefore a good idea to clean the probe regularly with the included cleaning card. Cleaning is best performed when the PosiTector SmartLink is powered down. 1. Clean the probe with the include cleaning card 2. Wirelessly Connect the PosiTector probe to the smart device using the PosiTector App 3. Zero the probe 4. Measure the included check shim to verify accuracy 5. Measure the burnished replica tape See How to Measure for more detailed measuring instructions.  The PosiTector App connects a PosiTector SmartLink to your iOS device enabling you to use PosiTector 6000, DPM, SPG or RTR-H probes on your device without the need for a conventional gage body. Screen fonts, brightness and displayed language are inherited from your smart device settings. Currently, the PosiTector App has language support for English, Spanish, French, German, Chinese and Korean. Screen orientation is fixed to portrait only, rotation to landscape is not supported. Stored batch readings, images and notes are all stored in the PosiTector App (on your smart device). The number of stored batch readings is only limited by the memory available on your smart device. If the application is removed or a menu Reset is performed, all stored readings and associated data is permanently erased.

Wirelessly Connecting the PosiTector App to the PosiTector RTR-H probe 1. Power-up the PosiTector SmartLink and connected RTR-H probe by pressing the LED button. The button will blink blue. 2. Select the PosiTector SmartLink App icon on your smart device. A menu containing the following options will be displayed:

3. Select Continue. A list of available PosiTector probes (listed by connected probe type and serial number) will be displayed. Select the desired PosiTector SmartLink to connect. The LED button on the PosiTector SmartLink will illuminate solid blue when successfully connected.

User Interface

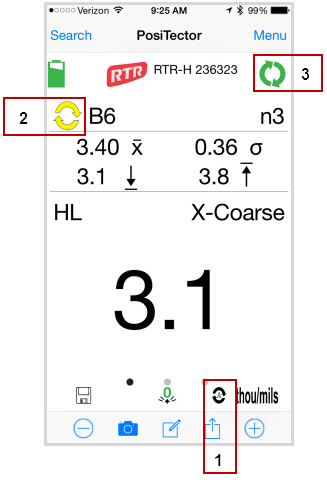

Main Navigation Bar In the above example, Search and Menu navigation options are available. Search returns back to the list of available PosiTector SmartLink devices. Menu accesses the Main Menu SmartLink Status Bar The above example indicates that the PosiTector SmartLink battery status is full and connected to a PosiTector RTR-H probe (serial number: 236623). Measurement Area

The measurement area will change depending on the connected probe type and selected modes. Modes Icons and Units Carousel Tip: Some views contain interactive areas. For this reason we recommend swiping horizontally across the Mode Icons and Units bar. Tool Bar

The PosiTector SmartLink acts as a relay between the PosiTector probe and PosiTector App using wireless Bluetooth Smart (BLE Bluetooth Low Energy). No pairing required! Auto-pairing Bluetooth connection works up to 10m (30 feet) away. Information specific to currently selected modes and user calibration adjustments (specific to each probe) are retained within the PosiTector SmartLink. This allows for seamless switching between smart devices (phone and tablet).

Connect a Probe When powered-up the PosiTector SmartLink automatically determines what type of probe is attached and does a self-check. The probe type, model and serial number display are displayed when found within the app's Search screen.

Power-up / Power-down Tri-Color LED Button LED Color Status

The PosiTector RTR-H probe measures burnished Testex Press-O-Film replica tape to produce peak-to-valley surface profile height measurements.

More probe information is available at www.defelsko.com/rtr Factory Calibration Certification Written Calibration Procedures are available online at no charge. http://www.defelsko.com/quality/calibration_procedures.htm

1. Prepare the test surface Prepare the test surface

Burnish the replica tape (create a replica) Pull a single adhesive-backed replica tape free of its release paper. A "bull's eye" circle of paper should remain on the release paper (it is not used for measurement). Apply replica tape to blasted surface. Press the adhesive-backed ends of the paper to hold it firmly in place during the burnishing process. Firmly compress replica film using the rounded end of the included stainless steel burnishing tool. Apply sufficient pressure in a circular and x-y rubbing motion to produce a replica with a uniform pebble grain appearance. It normally takes 30 to 60 seconds to fully compress all parts of the film on most surfaces. In general, too much compression is safer than too little. After burnishing is complete, remove the replica tape from the surface.

Prepare the probe Power-up the PosiTector SmartLink by pressing the LED button. Zero the probe by simultaneously pressing and holding both probe buttons firmly until the arrows point outward. Do not place anything in the measurement opening during this procedure.

Measure the included check shim to verify accuracy. Ensure the correct grade of replica tape, Coarse or X-Coarse, is displayed in the upper left corner of the measurement area. Measure

To position the tape, move The TestexTM Press-O-FilmTM replica tape to the back of the probe and align the two dots (printed on replica tape) with arrows on both sides of the measurement opening.

If you are using older TestexTM Press-O-FilmTM replica tape that does not have the printed dots, simply align by centering the tape within the measurement opening. Once positioned, firmly press both probe buttons simultaneously and hold until the measurement is displayed. During measurement, a constant anvil pressure is applied to the replica tape regardless of how hard the two buttons are pressed. The PosiTector RTR-H probe automatically subtracts the 50.8 um (2 mil) of incompressible polyester film. No further adjustments are required.

Calibration and Verification of Accuracy Calibration PosiTector RTR probes ship with a Certificate of Calibration showing traceability to a National Metrology Institution. For organizations with re-certification requirements, probes may be returned at regular intervals for calibration. DeFelsko recommends that customers establish calibration intervals based upon their own experience and work environment. Based on DeFelsko’s product knowledge, data and customer feedback, a one year calibration interval from either the last date of calibration, date of purchase, or date of receipt is a typical starting point. Written Calibration Procedures are available online at no charge. http://www.defelsko.com/quality/calibration_procedures.htm Verification Place the check shim into the measurement opening. The average of several readings should be within the combined tolerance of both the probe and the shim. If not, the probe may need to be returned to your dealer for service. The check shim is specifically intended for the PosiTector RTR-H. The probe is designed to measure burnished replica tape within a limited measuring range and automatically subtracts 50.8 um (2 mil) from height measurements to account for the incompressible polyester film. Therefore plastic shims intended for other instruments such as coating thickness gages will not be measured properly.

PosiTector RTR-H functions are menu controlled. Access them by selecting Menu in the upper right of the PosiTector App display.

The Main Menu contains the following sub-menu's... Select Exit to close the menu.  Zero 1. Select Zero from the Cal Settings menu 2. Simultaneously press and hold both probe buttons firmly until the arrows point outward. Do not place anything in the measurement opening during this procedure.

Shortcut: Simultaneously press and hold both probe buttons firmly until "0" displays (arrows do not display as in above). This can be performed from the main measurement screen without having to access the menu. Reset Current Cal Tape Grade Coarse

Linearize mode HL An undesirable characteristic of replica tape is that measurements made with analog spring micrometers are most accurate near the middle of each grade's range and least accurate at the outer ends of each grade's range. That is why two other grades, Coarse Minus and X-Coarse Plus, are used to check and, if necessary, adjust measurements at the lower and upper ends of the primary range of 20 - 115 um (0.8 - 4.5 mils). Inside the primary range, the upper end of Coarse grade's range and the lower end of X-Coarse grade's range share a 38 - 64 um (1.5 - 2.5 mil) "overlap" region. Current Testex instructions describe a relatively complicated and time consuming procedure (the average of one reading using Coarse grade and one reading using X-Coarse grade) that is used to knit the Coarse and X-Coarse sub-ranges together to achieve reasonably accurate readings over the primary range. This method is a compromise between accuracy and ease of use. When the Linearize box is NOT ticked, the PosiTector RTR-H displays a height value of H comparable to the value an analog spring micrometer would display after the 50.8 um (2 mil) of incompressible polyester substrate has been subtracted. In other words, it is the average of the maximum peak-to-valley distances obtained by measuring the thickness of the replica tape without any correction. When the Linearize box IS ticked, the PosiTector RTR-H displays a more accurate peak-to-valley height measurement HL that has been adjusted for the non-linearity of replica tape. There is no need to average 2 or more replicas from different grades of tape AND there is no need to subtract the 50.8 um (2 mil) of incompressible polyester substrate. Ensure the proper tape grade, Coarse or X-Coarse, has been selected and appears in the upper left corner of the display. During measurement, if the linearized measurement falls outside of the selected tape grade's range, a more suitable tape grade will be suggested to perform the measurement.  The PosiTector App uses your smart device's storage for recording measurement data. Stored measurements can be reviewed on-screen, printed (AirPrint), shared via email (PDF, CSV) or synchronized with cloud-based PosiSoft.net. Measurements are date and time-stamped (using date/time from smart device). The following options appear within the Memory menu. Additional options may appear depending on the connected PosiTector SmartLink and probe type. New Batch The Shortcut: When a batch is open, press the LED button on the PosiTector SmartLink or The following 3 screen views are available when a batch is open (Memory ON). Swipe your finger horizontally across the screen to switch between views.

Batch Summary View

Use the Tool bar icons to change the batch name, add batch notes and attach an image.

Ignore Readings are retained within the batch but are excluded from the report's statistical summaries and charts. Ignored readings are highlighted within the Batch Readings view (shown below).

By default Ignored Readings are not included on reports. For inclusion, toggle the Hide Ignored Readings within the Batch Report Configuration. Ignored Readings will display has highlighted within the readings section of the report, but are excluded from the statistical summary and chart. Delete Reading permanently removes the selected measurement from the current batch.

Cancel exits the menu.

Batch photos can be included in reports (default) and synchronized with PosiSoft.net. The photo can be resized or hidden from reports within the Memory >> Batch Report Configuration menu.

Change the batch name and add batch notes using your smart device's keyboard or dictation tools.

Batch names/notes appear on reports and are included when measurement data is synchronized with PosiSoft.net.

Share/view professional PDF reports and CSV data instantly via email, AirPrint, Dropbox or other applications on your smart device.

Generate PDF reports instantly and share via email, AirPrint, Dropbox or other applications on your smart device.

Batch reports can be customized within the Batch Report Configuration menu.

Export

Batch Readings View Lists all readings contained in the current batch. New readings are added to the list instantly as they are taken.

A note and/or photo can be added to each individual reading. Notes and photos can be displayed in batch reports and synchronized with PosiSoft.net.

Batch Chart View Display an x-y chart of measurements contained in the current batch. The chart is instantly updated as measurements are taken.

Pinch the active region of the chart to zoom the view. Open

Additional measurements can be added to existing batches only if the original probe is attached to the PosiTector SmartLink.

Close Batch measurement data is retained when a batch is closed. Delete Select batches for deletion, then select OK. Or select Delete all batches for all probes to permanently delete all measurement data from the smart device (phone/tablet). If the batches have been synchronized or copied to PosiSoft.net, a copy will remain there.

Batch Report Configuration

Select Preview Report to review your changes.

Batch Report

Share the report instantly via email, AirPrint, Dropbox or other applications on your device.

See Synchronization section for details on... Sync Now Copy to PosiSoft.net Copy from PosiSoft.net When toggled ON, the

Clear

SmartLink Info

The PosiTector SmartLink Serial Number and unique Key are required to register for a free PosiSoft.net account. An account is not required for Copying Batches To/From PosiSoft.net.

Change Units Switching units will turn OFF Statistics and close Memory.

SmartLink Lock Toggle the SmartLink Lock

See Synchronization section

Reset Suggestion: It is recommended that you synchronize all stored measurement data to PosiSoft.net prior to performing a Reset. This provides a backup solution in case measurement data has been deleted in error. Data on PosiSoft.net is not affected by a Reset. There are two available Reset options: Menu Reset and PosiTector SmartLink (LED Button) Reset Menu Reset (PosiTector App) -All stored batches, measurements, images, notes, annotations are deleted. -All calibration settings (adjustments) for all probes are cleared and restored back to factory settings. (provided PosiTector SmartLink is ON and connected to App). To keep calibration settings, power off the PosiTector SmartLink prior to performing this menu Reset. Settings are returned to the following: Memory = OFF LED Button Reset (PosiTector SmartLink) -All calibration settings (adjustments) for all probes are cleared and restored back to factory settings. Settings are returned to the following: Units = Microns  Sample measurement data can be loaded into the PosiTector App by selecting Load Sample Batches when the app is first opened. An internet (data) connection is required to load sample batches from the cloud.

To view the sample batches, select Open from the Memory menu. They are identified with the word "Sample" in the batch name. 1. Select Menu at the top left of the App. 2. Select Memory and then Open. The following screen will appear:

3. Select desired batch to open (touch selection). Sample batches can be deleted from the PosiTector App by selecting Delete from the Memory menu. Select individual batches for deletion and select OK or select Delete all batches for all probes to delete all measurement data.

Sample Batches cannot be synchronized with PosiSoft.net.  PosiSoft.net is a free web-based application offering secure centralized management of measurement data. It is accessed using a standard internet browser from any location in the world.

Synchronize (Sync) with PosiSoft.net Synchronizing (Sync) is a two-way communication process between the PosiTector App and PosiSoft.net (no registration required). WiFi/cellular internet data connection required. Stored batch data including measurements, photos, notes and annotations are included in the synchronization. After synchronization, data on the PosiTector App and PosiSoft.net will match (be the same). New changes made to either will be included and merged during the next synchronization process. Tip: Prior to synchronizing, it is good practice to change batch names to something more meaningful. This helps identify the batch in the future. Example: Rename "B4" to "Job142-14" or "Section83". Synchronization can be triggered either manually (Sync Now) or automatically when batch data changes (Auto Sync).

Sync Now (Memory Menu)

Auto Sync (Setup Menu)

The example below demonstrates the PosiTector App with Memory and Auto Sync on. A reading has been stored within the app and is in the process of synchronizing with PosiSoft.net.

(1) Auto Sync icon (appears when mode is on) (2) Batch Synchronization status with PosiSoft.net

(3) Synchronization transfer status with PosiSoft.net

If successful communication is not established after a period of time, the app will stop trying and the red icon will disappear. Ensure that your smart device has an internet/cellular data connection. Auto Sync is an ideal backup solution for your measurement data. Data can be copied back to the PosiTector App on the same smart device or another (ideal for switching between smart devices). To view/interact with synchronized data on PosiSoft.net, registration of your PosiTector SmartLink is required (free account). To transfer all stored batches, select Sync Now.  Copy To/From PosiSoft.net (Memory Menu) Sync Now synchronizes all batch data for all probes associated with the connected PosiTector SmartLink. Sometimes only a single batch or select batches is desired for transfer. Copy to or Copy from PosiSoft.net allows the selection of single or multiple batches for transfer. Ideal solution for switching between smart devices (phone and tablet). Pickup exactly where you left off.

Copy to PosiSoft.net

The selected batches will be copied to PosiSoft.net and you will be returned back to the main measurement screen. If the batches already exist on PosiSoft.net you will be prompted with an overwrite warning message. "At least one of the batches you selected already exists on PosiSoft.net. Press OK to overwrite existing batches. Pressing Cancel will not copy the batches" If OK is pressed, the existing batch on PosiSoft.net will be overwritten. This action cannot be un-done. The copied batches will be identified with a

The

Copy from PosiSoft.net

The

Once associated, you can Copy To and From PosiSoft.net with or without a PosiTector SmartLink connected.  Switching between Smart Devices The PosiTector SmartLink easily switches between multiple smart devices (i.e. phones and tablets). Batch data can be transfered between devices using the Copy to and Copy from PosiSoft.net features. For example, you may wish to collect measurement data in the field with a smart phone and then document and generate reports on a tablet back at the office. SmartLink Lock must be off for other devices to be able to connect to the PosiTector SmartLink. Ensure this is off prior to switching smart devices. PosiTector SmartLink only (no batch data) Open the PosiTector App on another smart device. Select the PosiTector SmartLink (identified by connected probe type and serial number) from the list. Batch measurements taken on the previous smart device are not present by default. To get batch data from a previous device see below. PosiTector SmartLink with batch data Ensure the PosiTector SmartLink is disconnected from the original smart device. Close the PosiTector App or return to the Search screen. Open the PosiTector App on another smart device. Select the PosiTector SmartLink (identified by connected probe type and serial number) from the list. Select Copy from PosiSoft.net from the Memory menu and choose the desired batches to include in the copy. Press OK. The chosen batches will be copied from PosiSoft.net to your smart device. Open a batch by selecting Open Batch from the Memory menu. Continue right where you left off.

Once associated, you can Copy To and From PosiSoft.net with or without a PosiTector SmartLink connected.  Limited Warranty, Sole Remedy and Limited Liability DeFelsko's sole warranty, remedy, and liability are the express limited warranty, remedy, and limited liability that are set forth on its website: www.defelsko.com/terms

DeFelsko and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and in other countries. iTunes and AirPrint are trademarks of Apple Inc., registered in U.S. and other countries. Other brand or product names are trademarks or registered trademarks of their respective holders. Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not responsible for printing or clerical errors. This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. |